The Science of Extruded Multi layer tubing

18 April 21

Multi-Layer Extruded Tubing

The multi layer tubing extrusion involves the technology that processes more than two polymers at a single time. The polymers co-join together through extrusion to formulate the multi layer tubing that has multiple layers.

The simple way of inputting two or more two extruding materials into the die can help in producing different types of tubing solutions. The instructions fed into the computer decide the outcome of the extrusion process. They can produce a variety of tube-like single, double or multi layer tubing.

This is a very complex procedure that makes use of incorporating different properties of different polymers. It takes into consideration the bonding features and resistance qualities. This is even possible for polymers that have divergent qualities.

Co-extrusion of Different Polymers

The multi layer tubing co-extrusion has to face many trials for creating evenly walled tubes. The construction of walls that have uniform thickness can assure efficiency in results and outcomes. The quality of different polymers can vary vastly. The stickiness and the melting points of the different materials can create hindrance and even de-laminate the whole tube if not co-extruded properly.

It is common for different materials to react differently to the same process. Moreover, the adhesive nature of each material can cause instability in the interface of the layers. When polymers that have a low melting point integrate, they can cause an unstable formation in the tube structure.

This is why it is important for the materials to become chemically compatible to integrate them into a multilayer tube. These polymers grade differently hence they cannot form a strong bond without co-extrusion. Therefore the tubing materials must go through rigorous processing to laminate into a single, double, or multilayer tube.

Co-extrusion for Multi Layer Tubing

The constant improvements in the technology for making extruded processes can help the medical field. These techniques are very helpful in manufacturing multilayer tubes that can prove to be very helpful in aiding many medical procedures. The tube takes a lot of advanced techniques and methods to come into existence. The idea behind manufacturing them using co-extrusion is to produce a solution to many complex medical situations.

It is by far the most improved method for creating a passageway for other medically related tools. Although this method is quite advanced, it requires very little manual power for production. Thus, the cost cuts to vary nominal rates.

The multilayer tube is very robust in nature and can fulfill the multiple requirements of different procedures. It even increases the efficiency level and encourages the use of these tubes not only in complex but regular medical procedures as well.

Researchers are coming up with ways to miniature is the structure of the tube such that it becomes the least invasive tool in medical history. The size is so minute yet workable at the same time to perform operations. The miniaturization of the size does not affect the efficiency; rather it adds more functionality to the tube by adding co-extruded polymers that bring their own qualities to the tube.

Understanding the Multi Layer Tubing

There are many tubing solutions available that we are familiar with. They include single, double, and multi-layer tubing in the medical business. As we proceed through the tubing solutions, they become complex when they have more layers. The more number of layers indicates the high level of complexity of the tube structure.

A multilayer tube has a lot of layers which takes precision and keen development techniques to manufacture them. It takes a high level of engineering to extrude different layers and make a customized tube. The versatility of the tube matters a lot because it shows the ability of the multilayer tube’s performance variety. Yet researchers are still coming up with more ways to upgrade the existing medical tubes.

The level of hard work and thought that goes into their construction is commendable. Adding more layers means more work. When extruding different materials, their properties can make or break the deal. Sometimes, you can make use of similar materials that have similar properties but in other cases, you may need to use different materials that can differ totally. Thus, it is not possible to make a multiple-layer tube using different materials without extrusion.

Usage of Multi Layer Tubing

There are multiple uses and situations where a multilayer tube can be very helpful. It is famous for performing diverse medical applications with great ease. The idea behind using a multilayer tube is to make the least invasive entry and still being able to perform the procedure with efficiency and precision.

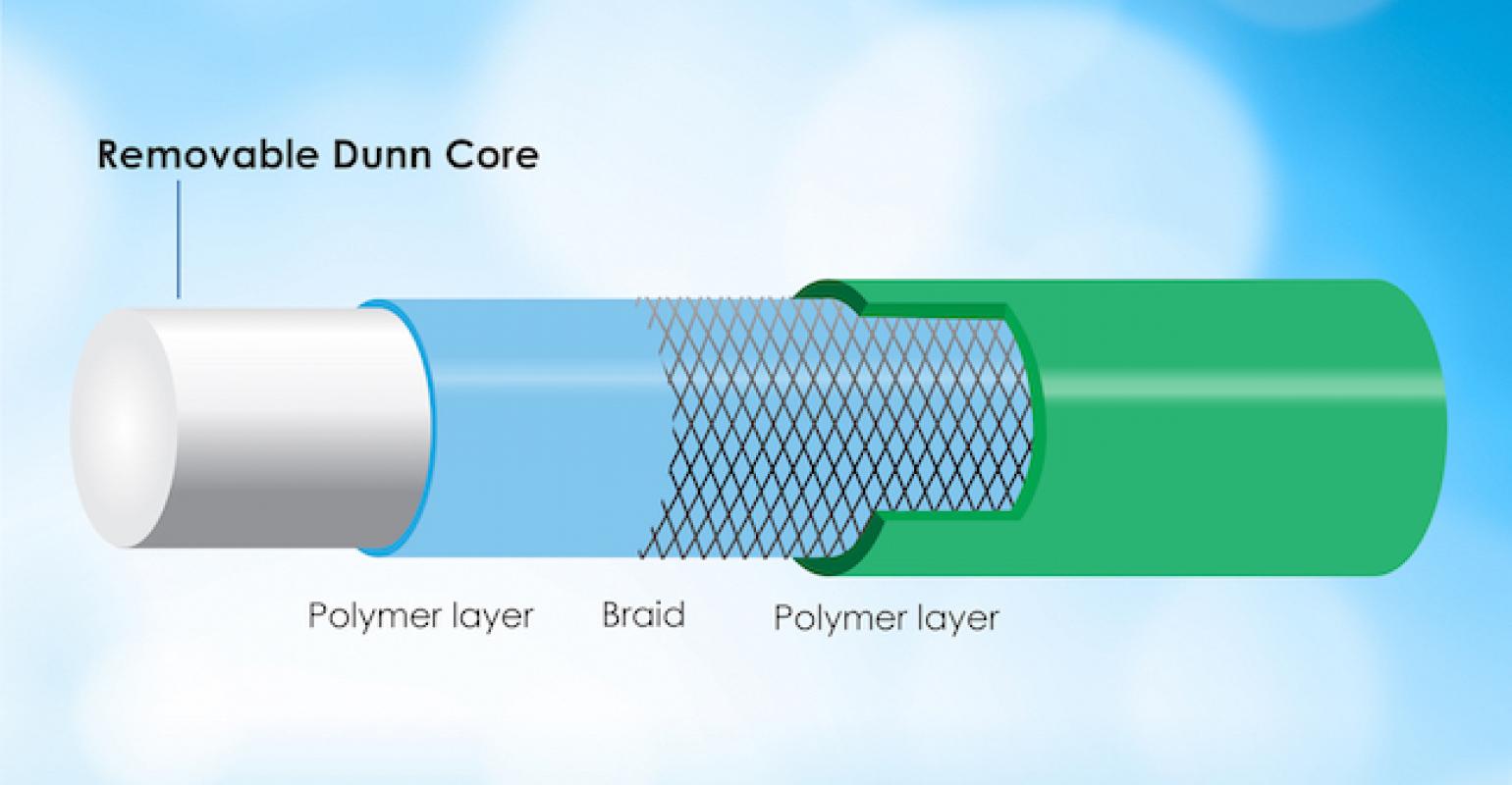

For example, it is suitable for percutaneous catheters used in angioplasty. It is even the most feasible choice for balloon catheters and introducing stents during angioplasty. The lubricious quality of the innermost layers allows easy passage. It constructs of a very high-quality polymer that facilitates the way for catheters over the guiding wires. The bonding ability of the middle layer can connect the internal and external layers.

Moreover, it can create a vacuum for complicated procedures as well. It is beneficial to use a multi-layer tube to deliver and evacuate other medical tools like operational scissors and cameras.

Conclusion

The most important thing in co-extruding multi layer tubes is their design. There are many complex applications like angioplasty and intravascular surgeries that make use of such tubes. So, it is important for the polymers used in each layer to complement each other even if they are dissimilar in nature.

In order to achieve optimized extrusion results for the device to work properly, the tube must pass some rigorous testing standards. In addition to the existing methods for making extrusion implementable, researchers have come up with easier and efficient ways that facilitate production. Eventually, this will add more efficiency and functionality to the existing tubes by making them a preferable choice. It is possible in the near future that we will have the most modern and least intrusive tubing solution.

For More Information, Contact Us Today!